DTF printer with white ink Printing machine is a way to make very high-quality, full-color digital transfers for application to fabrics of all kinds.Dtf printer white ink heat press printer, film printing film or printing film, ink printing ink can also be called printing ink DTF works on many different garment materials: cotton, polyester, nylon, treated leather, polyester fabrics, 50/50 blends, light and dark fabrics, etc.The pattern after DTF ironing has a texture like PU glue, strong stretching resilience without deformation, soft hand feeling, dry film surface, and easy hot tearing. DTF printing release film can easily achieve instant tear effect.

Our DTF printer adopts Epson original print head and Hoson board, which can support 2/3/4 head configuration at present, with high printing accuracy, and the printed clothes patterns are washable. The new powder shaker independently developed by us can realize automatic powder recovery, save labor costs, facilitate use and improve work efficiency. Stylish and simple in appearance, stable and sturdy frame, with 2 Epson XP600 nozzles, color and white output, you can also choose to add two fluorescent inks, bright colors, high precision , guaranteed printing quality, powerful functions, Small footprint, one-stop service of printing, powder shaking and pressing, low cost and high return.

Imprint of arts on T

-shirts to captivate all kinds of hobby niche, such as music and events.

Hoodies

Colorful prints on hoodies to showcase dynamism and Advertisement

Cap

Logo prints on caps for advertisement and promotional purposes, and sports events.

Canvas Bag

Logo and brand label promotional design prints on canvas bags.

Pillow

Unique customization to add thing on pillows and keep the memory alive.

Shoes

Different array of trendy designs on shoes for additional styles

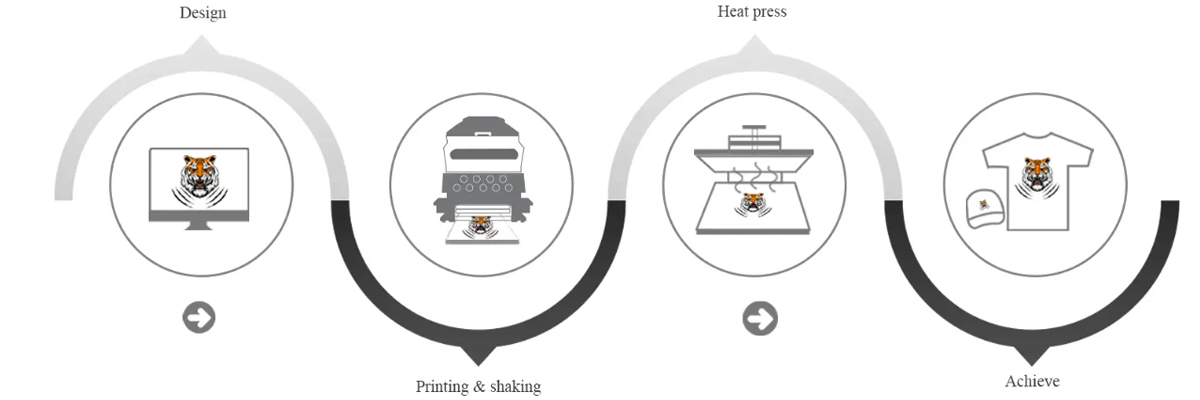

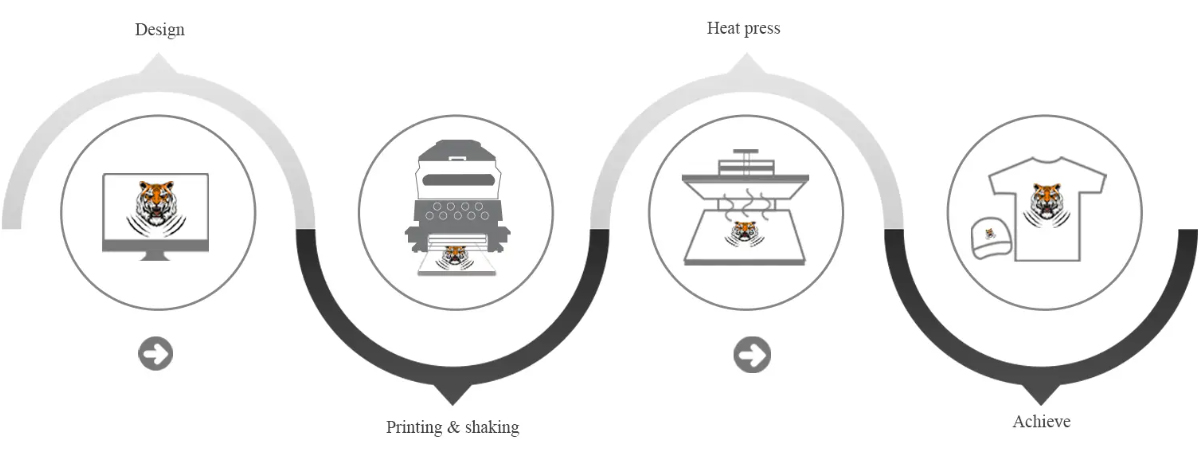

How to Print on a T-shirt with DTF (Direct To Film) ?

In quick summary, your DTF printer is going to print on a film that has a direct to textile ink coating on it. Then a powder which is the adhesion property is added to it, After which it is heated to a specific temperature. 0nce the temperature as been achieved, the film with the design or image is then pressed onto the fabric. You can do multiple substrates, and the best thing about this technique is that the press time is very low. Overall, about 10 seconds.

Step 1 – Printing the designs on the film The first step is to insert the pet film onto the printer tray Make sure to print the entire design in white before printing the multi-colored layer on the white. Do not forget to flip the design before printing

Step 2 – Adding the desired colors

Add the desired colors, The printer has several print head that performs different printing action. The first head applies the colors which is a blend of CMYK color on the film. Then the second head applies the ideal amount of white under the base perfectly on top of the colors., The second print head does this in an accurate alignment to prevent the white from showing,Remember, this alignment is done on the film sheet on the fabric.This is because the bumps on the shirt will affect the overall design So applying it to the film ensures that the final design is crisp with neat edges. You can’t achieve this using the traditional screen-printing process.

Step 3 – Adding the unique powder

After printing, the printer sends the film to the powder shaker unit, where a unique powder adhesive coating is added to the film evenly while it is still wet, into the loop. This powder is responsible for the infamous soft touch DT prints always have. Ink and a thin cat of adhesive powder are the two main ingredients in direct to fabric printing. The excess powder is therefore beaten of the film in the powder shaker machine and then it is passed to the belt drier to melt of the powder and to ensure that it is gelled to the ink

Step 4 – High-pressure heat pressing

The next step after printing, adding powder, and shaking it off is the heat press.It is simply taking the transfer film out of the powder shaker machine and placing it on the fabric that is already on the heat press.It should be pressed for about 10 seconds in high pressure.The hot-peel sheet is then peeled off after allowing it to cool off completely. Then a finishing sheet is placed on the fabric to further drive the ink into the fabric in high temperature.